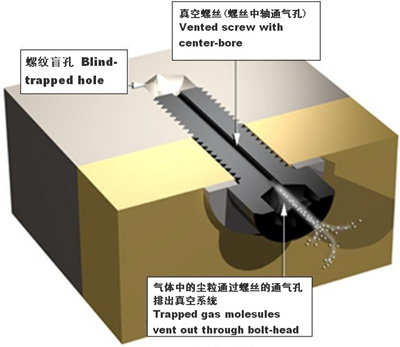

真空螺丝工作原理 vented screw working principle

又称排气螺丝,打孔螺丝,是用于真空系统中的螺丝。真空螺丝外型与普通螺丝几乎一样,差别在于真空螺丝中轴从头到尾有一个贯穿的孔。在真空系统设备中,螺丝孔一端是封闭的,当螺丝锁入时,会有空气被"关"在螺丝尾端及螺丝孔底端之间(螺纹盲孔)。如用普通螺丝,当系统抽真空时,这些被"关"住的空气,会因为螺丝的阻挡而不会被迅速抽走,反而会在抽真空后从螺纹槽缝隙中缓慢排出,对真空系统造成影响甚至污染,使系统真空无法达到目标值。如果采用真空螺丝,盲孔内的气体会从螺丝中央贯穿的孔被快速抽走,让系统真空达到目标值。

Vented screw is used in vacuum system/machine, whose appearance is almost the same with the ordinary screw , the only difference is that there is a vented bore through the screw center. In vacuum system equipment, screw hole at one end is closed, when screw locking in , there will be air "trapped" in the blind-trapped hole (the space between the end of screw and the bottom of the screw hole, see the picture). If using ordinary screw, the trapped air cannot be pumped down quickly but outgas from the screw slot slowly, it will affect the vacuum system badly even polluting, and makes system can not reach the target value. If using vented screw

with center-bore which provides an outgas path,the trapped air can be pumped down quickly, that makes the vacuum system reach the target value.

评论

登录后你可以发表评论,请先登录。登录>>